Product Series

Contact Us

Telephone: +86-187-6548-6789

WhatsApp: +86-139-5388-5161

E-Mail: boss@sdtsgm.com

Address: Qiujiadian industral Park, Qiujiadian Town,Taishan District, Tai'anCity, Shandong Province

Wooden wire drum

Hello Dear Visitor, For any style you browse, our company can be customized (style, size, etc.), please contact us or please leave your contact information, we will contact you at the first time.The following is a detailed introduction to wooden bobbins:1, classification and materialWooden bobbins can be divided into various types according to their material and construction, mainly including:Iron and wood combination of wooden bobbins: composed of solid wood strips and metal strips, the solid wood strips are combined to form the disk surface and barrel, and the metal strips are reinforced at the outer ring of the disk surface and the axle holes to enhance the overall load-bearing and tension. This kind of wooden tray is often used for cable line put away, storage and transportation.Solid wood board wooden disk: all composed of solid wood, no metal bar support, relatively low strength, but also can be used for cable put away line, especially for steel wire, iron wire loading.Plywood wooden tray (also known as fumigated board wooden tray or export wooden tray): made of multi-layer timber boards glued together, with high strength and durability. These wooden bobbins are fumigated to meet export requirements, so they are also often called fumigated bobbins or export wooden bobbins.The main materials of wooden bobbins are natural pine or artificial lumber (such as particle board, plywood, etc.). Natural pine wood has a single component, while artificial plates have the advantages of high strength, durability and easy processing.2, characteristics and advantagesCustomizability: Wooden bobbins can be customized according to different needs, such as size, shape, load-bearing capacity, etc., to meet the needs of different industries and customers.Environmental protection: With the improvement of environmental protection consciousness, modern wooden bobbins are mostly made of environmentally friendly materials to avoid pollution to the environment. At the same time, the production process also focuses on low-carbon processes and the use of recycled materials.Anti-mold, anti-moth and water resistance: In order to improve the service life of wooden bobbins and protection performance, the production process may use some preservatives and waterproofing agents to enhance its anti-mold, anti-moth and water resistance and other characteristics.3, production processIn the production process, it is necessary to ensure the dryness and quality of wood, as well as the precision and firmness of splicing. For the ironwood combined wooden tray, the reinforcement of metal bars is also needed to improve the overall strength.4, Application fieldThey not only provide a safe and reliable packaging method for these products, but also facilitate the storage and transportation of the products.5, SummaryIts high strength, durability, customizability and environmental friendliness have made it popular. With the continuous progress of technology and environmental protection requirements, the future production process and material selection of wooden bobbins will be more advanced and environmentally friendly.With the continuous progress of technology and environmental protection requirements, the future production process and material selection of wooden bobbins will be more advanced and environmentally friendly.will be more advanced and environmentally friendly.

Keyword:

Product Description

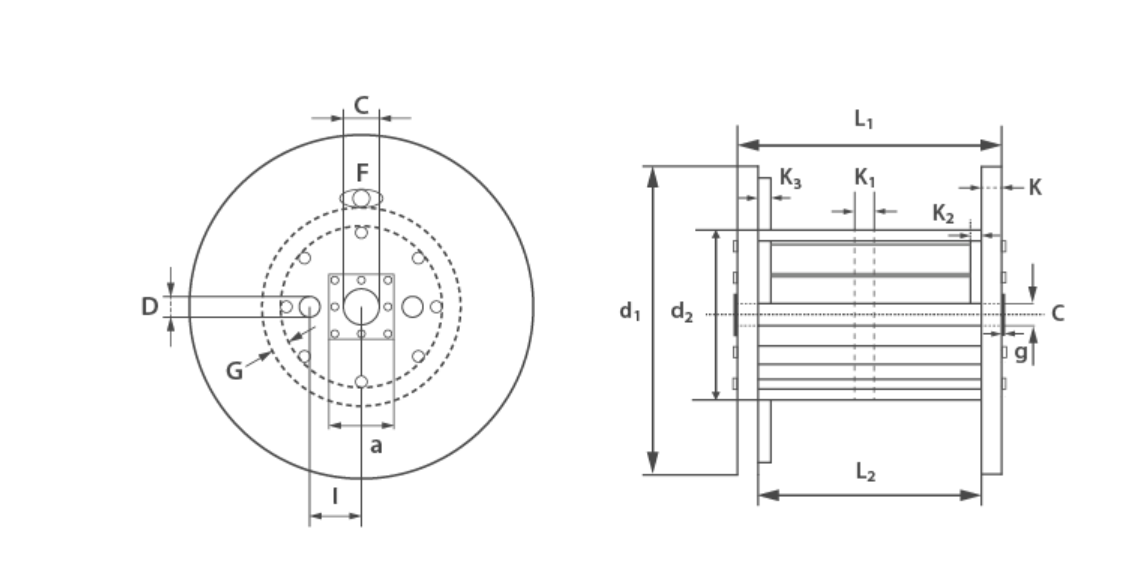

The table contains some examples of standard dimensions.All dimensions are given in millimetres.

| Spooltype | 6 | 7 | 8 | 9 | 10 | 12 | ||

|---|---|---|---|---|---|---|---|---|

| diameter | Flange | d1 | 600 | 710 | 800 | 900 | 1000 | 1250 |

| Core | d2 | 300 | 355 | 400 | 450 | 500 | 630 | |

| Boards | Flange thickness | K | 46 | |||||

| Core bars groove width | G | 21 | ||||||

| Borings | Central bore | C | 85 | |||||

| Drive hole | D | 30 | 40 | 50 | 65 | |||

| Cable passage | F | 40 | 50 | 65 | ||||

| Distance between D and C | I | 100 | 160 | |||||

| Winding width | L2 | 400 | 560 | 670 | ||||

| Overall width | L1 | 520 | 690 | 710 | 890 | |||

Wooden Cable Drum is a core tool used in the electrical, telecommunications, and construction industries for storing, transporting, and deploying cables. Its design, application, and advantages can be summarized as follows:

1、 Core Features

Material and Structure

Using sustainably managed wood (compliant with ISPM-15 standards) to ensure environmental compliance.

Cylindrical design, consisting of circular flaps on both sides and a central axis (core). The diameter of the flaps is usually 300mm to 1000mm or more, and the diameter of the central axis is 36mm to 48mm, which can accommodate cables of different specifications.

Some models use plywood baffles to reduce weight and improve cost-effectiveness, making them suitable for disposable packaging scenarios.

physical property

Lightweight: Compared to steel cable reels, wooden structures are easier to handle and reduce labor costs.

Durability: After moisture-proof and anti-corrosion treatment, it can be reused multiple times to extend its service life.

Carrying capacity: The single disc can carry up to 100kg to several hundred kilograms, meeting industrial grade requirements.

2、 Core application scenarios

Power industry

Used for storing and transporting high-voltage cables and low-voltage distribution lines, protecting cables from mechanical damage.

As a temporary support structure for cable deployment in substation construction and power grid renovation projects.

Telecommunications industry

Standardized packaging units for fiber optic cables and copper cables ensure signal integrity during long-distance transportation.

Used in conjunction with fiber fusion splicers to achieve rapid deployment and fusion splicing of optical cables.

Architecture and Engineering

Temporary wiring at the construction site, such as tower crane power supply and construction lighting cable management.

Temporary power/network deployment for large-scale events such as music festivals and sports events.

Industrial manufacturing

Cable supply system in automated production lines, such as flexible cable storage for robot arms.

Pre assembly and transportation of cables for heavy equipment such as ships and aviation.

3、 Technical advantages

environmentally

The recycling rate can reach up to 90%, and the waste can be regenerated into wood chips or biomass fuel through crushing, pressing, and other methods.

Compared to plastic cable reels, production energy consumption is reduced by 60% and carbon emissions are reduced by 45%.

economic

The cost of a single plate is 30% -50% lower than that of steel models, making it suitable for medium to short distance transportation scenarios.

Standardized design (such as DIN46397, IEC 60269) reduces inventory management complexity.

Operational convenience

Both manual and mechanical forklifts can be operated and adapted to different logistics environments.

Can be equipped with brake devices or detachable baffles to enhance deployment flexibility.

Packaging & Dispatch

Customer Feedback

Get a Free Quote

If you need more information about our products, please feel free to contact us, we will provide you with professional service personnel, we will reply promptly after receiving the information.

Related Products

Industry Applications

Fibre-optic Cable

Cords

Cable

Wire Rope

Cord

Aluminium Wire

Corporate Profile

Shandong Taisong Industry & Trade Co., Ltd. Located at the foot of the beautiful Mount Tai, it provides packaging services for global rope, net, wire and cable enterprises. High-tech enterprises mainly engaged in wooden wire trays, European standard wooden trays, American standard wooden trays, export fumigation-free trays, all-iron wire trays, plastic wire trays, and paper wire trays, and can provide commodity inspection performance sheets. Dangerous packaging export provides dangerous goods packaging certificate. The company is a professional packaging products manufacturer with a wide variety of products.

Certificates

FAQ

Q

Does it support customisation?

A

Yes, please contact us in time.

Q

Where to ship?

A

Qingdao port, Shanghai port.

Q

Payment method?

A

30% Deposit, L/C

Q

How long is the delivery period?

A

7-10 days.

Q

Do you provide samples? Is it free or extra?

A

After the price is confirmed, you can request a sample to check our quality counter display. If you need samples, we will charge sample shipping fee. However, the sample shipping fee is refundable after order confirmation.

Q

How can I get your quotation as soon as possible?

A

Email and message, mobile phone and WhatsApp will be online within 24 hours. Please send us your requirements and order information (product, quantity, destination port) and we will work out the best price soon.